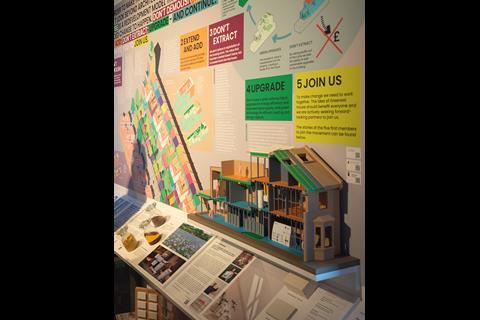

Pilot blends community-driven design, value uplift and energy upgrades to create a replicable model for sustainable, higher-density housing

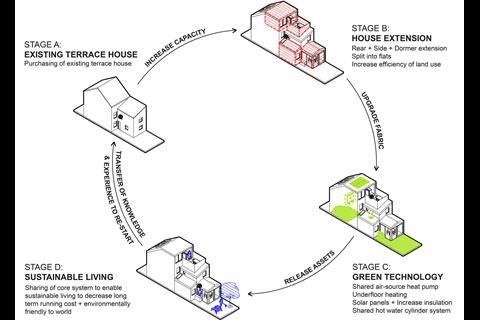

Spearheaded by design studio Office Ten, the Greenest House pilot project is rethinking the standard Victorian and Edwardian terrace homes, hoping to not only improve fabric performance but also increase housing density in a bid to solve the UK’s chronic housing shortage and the environmental impact of underperforming homes.

According to Office Ten co-founder Anders Luhr, the idea draws on the Norwegian concept of dugnad – a tradition of voluntary, collective effort towards a shared goal. “It is a way to get everyone together to work on required maintenance, such as painting, mowing the lawn and repairing shared furniture,” he says. “It is a very old tradition and used to be a way to get big tasks done, such as roofing or house building. The whole community would come together, chip in with their skills and abilities, to complete a shared task.”

Greenest House aims to apply this principle in a modern retrofit context. The project’s goal is to form a collaborative network of like-minded partners that contribute to the specification – not just once, but on an ongoing basis. Luhr says the team is focused on scaling impact, which means developing a financially self-sustaining system. “All change requires resources,” he says. “And the way we have chosen to unlock these are from the house itself.”

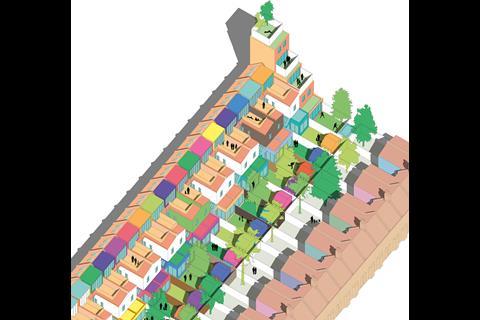

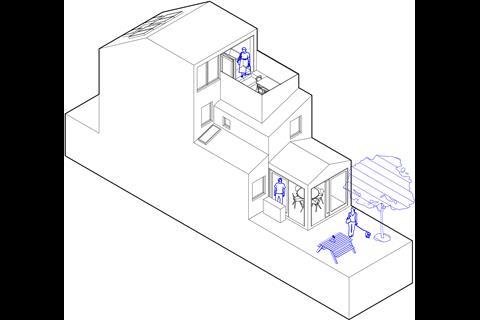

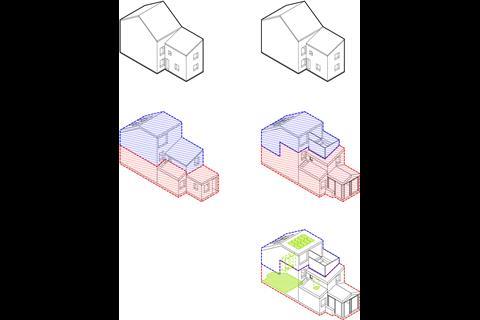

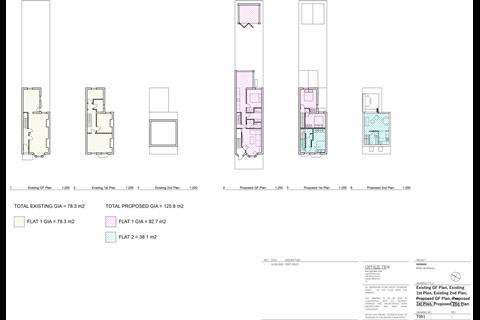

By extending and reconfiguring the layout, the proposal turns a single terrace into two flats – one larger unit suitable for a family, and a smaller one for a couple or individual. The reorganisation includes an additional stair to improve the spatial split. The ground floor and part of the first floor retain access to the garden, while the upper flat includes a roof terrace to ensure external amenity is provided for both units.

Key retrofit measures include improved insulation, triple-glazed windows, solar PV installations and the use of air source heat pumps (ASHPs) to reduce space heating demand. Office Ten claims the upgrade package can lower heating energy use by up to 90%, although further details on specifications and performance modelling are yet to be released.

The uplift in value from densification is intended to fund upgrades to the building’s external fabric. The team is targeting LETI’s best practice U-values for an unconstrained retrofit wherever possible. These benchmarks are designed to align with net zero operational energy goals and set a standard for thermal performance.

For example, LETI recommends a maximum U-value of 0.15 W/m²K for external walls, 0.1 W/m²K for roofs and 0.7 W/m²K for windows and doors. Floor upgrades are typically expected to achieve 0.1–0.15 W/m²K, depending on build-up. While reaching these values can be technically and financially challenging in a retrofit scenario, Office Ten is using them as a reference point to guide design decisions. Each property will be assessed individually to ensure interventions remain proportionate to the uplift in value delivered by the extension and conversion. “We need to keep the process going, so the upgrades will have to match the house value,” Luhr explains.

Greenest House is also building a network of manufacturing and supply partners aligned with its ethos. Five collaborators are already on board – each contributing systems or products for the pilot – with further partnerships expected. Selection is informal and based on mutual dialogue rather than fixed entry criteria. However, the team draws a clear line on standards. “We don’t accept any green washers,” says Luhr.

Quantified data is still being developed. Office Ten is working with an external partner to carry out energy performance and embodied carbon analysis, with results expected by the time of the UK launch. “We are currently working up a more detailed analysis of the design,” Luhr confirms, “so that we can give actual figures on what can be achieved.”

For specifiers, the scheme may serve as a small-scale but replicable model – one that connects retrofit to densification, value uplift to fabric performance, and product partnerships to long-term impact. As Luhr puts it, “It is all well and good to do one amazing project, but since we want to make a measurable impact, we need to think about scale.”

Collaborators

Adaptavate Creators of breathable low carbon and carbon-negative construction materials, including plaster and plasterboard

Brouns & Co Specialists in natural linseed oil paints and finishes

Cleveland Steel Leading suppliers of repurposed structural steel

EcoDuct Manufacturers of pre-insulated, energy-efficient and low CO2 ductwork

JAW Sustainability Sustainability consultant

Sisalwool Producers of natural fibre, breathable insulation

Ten & Sen Designers of sustainable, durable joinery and interiors

These partnerships are integral not only to the exhibition debut of Greenest House at Time Space Existence but also to its next phase: a full-scale implementation on a live retrofit site.

No comments yet