WarmFloor Pro is ideal for both residential and commercial structural floor construction

Building regulation changes in June 2022 mean that the current U-Value of ground floors for new-builds will lower from 0.25W/m²K to 0.18W/m²K.

In 2018, Milbank Concrete Products developed WarmFloor Pro, the insulated beam and block alternative that works as an effective ground floor solution to reduce heating costs and improve thermal performance. This system falls well within this new specification and can be part of a more sustainable build for the lifetime of your development.

Reduced construction costs, increased energy savings and speed and ease of installation make WarmFloor Pro a compelling alternative to a standard beam and block floor. A+ green guide-rated and fully certified, it is proven to be a must-have addition to any new, sustainable development, where keeping heating costs low is paramount.

WarmFloor Pro has already been successfully installed in thousands of new-build projects across the country, and we are well experienced in both supply only and Supply and fix requirements.

- Quotations available from drawings provided

- Uses our pre-stressed beams, both T155 & D225, manufactured at our factory in Essex

- In-house design service available

- Installed by our dedicated team of trained installers

>> To send us your drawings for a fast and free quotation, click here

>> To download the WarmFloor Pro PDF brochure, click here

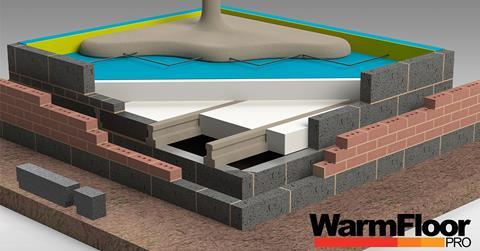

So, how does it work?

By replacing standard concrete infill blocks with a combination of rigid insulation modules (EPS panels) manufactured from lightweight closed cell expanded polystyrene, along with an EPS top sheet, damp proof membrane and structural concrete topping, we are able to achieve U-values as low as 0.07W/m²K.

We manufacture the concrete components and supply all the required materials (including the EPS panels) directly to site, removing the need to deal with multiple suppliers. Opting for WarmFloor Pro as opposed to a traditional beam and block floor can provide a comparable total cost for an insulated floor and is considerably easier, quicker and more economical to install.

Why choose WarmFloor Pro flooring over traditional Beam & Block?

- Sustainability: A+ green guide-rated, 100% recyclable and no waste created during manufacture. EPS has an ozone depletion potential (ODP) of zero and global warming potential (GWP) of less than 5.

- Thermal insulation: The use of EPS for thermal insulation in the construction industry leads to significant energy savings on heating and cooling buildings and a dramatic reduction in the emission of polluting gases. It therefore helps to alleviate the greenhouse effect and acid rain.

- 100% recyclable: Expanded polystyrene is one of the few building materials that can truly claim to be 100% recyclable. It can be reused in the manufacture of new EPS products, soil improvements and auxiliary compost material, as well as being added to other building materials. By fusion and granulation, it can be turned into simple products such as coat hangers and pens.

- Efficiency: No specialist skills or tools are required for installation – EPS panels are the same length as five traditional concrete blocks and are considerable lighter and easier to manage (~2kg).

- Bespoke: A wide range of EPS panel depths and grades are available to provide the most economical solution for developments while maintaining the highest levels of thermal properties.

- Compatible with underfloor heating: Plastic pegs push into the EPS panels and hold heating pipes in place, providing a quick and easy foundation for UFH installation.

About Milbank Concrete Products

“Delivering quality products, through a sustainably conscious supply chain, to help you build better.”

Our 75-plus years of experience in producing pre-cast concrete products for the construction industry makes us the perfect choice for a wide range of clients. We design, manufacture, deliver and install a range of components, from Hollowcore flooring planks to completely bespoke curved and helical stairs.

In 2021, we became one of the first UK pre-cast manufacturers to switch 100% of our manufacturing machinery from regular diesel to HVO biofuel. In doing so, we reduced our carbon output by 30%. Our expertise is trusted by the UK’s leasing housebuilders, and we are proud to contribute towards the nation’s reduction in CO2.

Build with us

To arrange an appointment, to submit an enquiry or to ask any questions, please contact our office directly on 01787 223931 or by emailing us at info@milbank.co.uk

For further information, please visit our website https://www.milbank.co.uk/