Live schemes in Bristol and Banstead are providing real-world evidence of what modern methods of construction can deliver. Richard Weeks explains how MMC is improving speed, quality and long-term performance in social housing development – and why early results matter.

For several years, modern methods of construction (MMC) have been positioned as a potential solution to the chronic under-supply of social and affordable housing. Faster delivery, higher quality and lower whole-life costs are frequently cited benefits. But until recently, many of those claims have remained largely theoretical.

For EDAROTH, that has now changed.

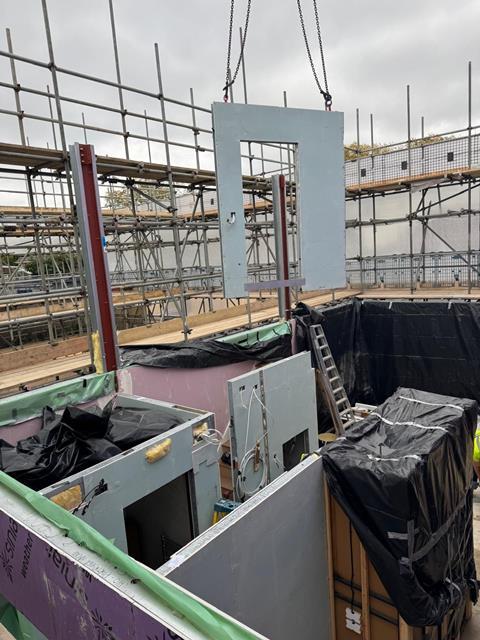

The SME developer and delivery partner currently has two schemes being built out using industrialised delivery: one nearing completion for Raven Housing Trust in Banstead, Surrey, and another under way for Bristol City Council, due to complete this summer. Together, they represent 37 homes across nine sites, including both houses and apartments, all for social rent.

More importantly, says Richard Weeks, operations director at EDAROTH, the schemes have provided real-world evidence that MMC can deliver what it promises.

“We’re in a very different position to where we were a year ago,” he says.

“We now have two schemes on site, one nearing completion and the other completing in the summer.

“What those schemes have allowed us to do is demonstrate to ourselves, to our clients and to the market that many of the benefits we’ve been talking about in relation to industrialised delivery and our model of delivery are actually real.”

Additive delivery, not displacement

Both schemes were developed as pathfinders for their respective clients. The Raven scheme comprises four sites delivering 12 houses, while the Bristol programme spans five sites delivering 25 homes, including 12 apartments.

But Weeks is clear that the rationale for industrialised delivery goes beyond the development of individual projects.

“Our use of manufacturing is as much about creating higher quality and higher performance homes through a scalable model at volume as it is about creating a new way of delivering that brings an additive supply of homes,” he says.

That emphasis on “additive” delivery is central to EDAROTH’s model. With a significant annual shortfall of social homes across the UK, Weeks argues that simply reallocating existing construction capacity will never close the gap.

“Until we find alternative ways to deliver, which is what our model is seeking to do, that won’t change,” he says. “That’s fundamentally what we’re trying to demonstrate, and that’s one of the reasons our clients are interested in the model.”

Factory quality, proven on site

One of the clearest benefits to emerge from the live sites has been quality. Homes are manufactured in a controlled factory environment, using precision manufacturing skills more commonly associated with advanced industrial production than traditional housebuilding.

“We’re making homes in a controlled factory environment, using people whose skill sets are in precision manufacturing,” Weeks explains. “That feeds through into the quality of the assembled homes and the performance of those homes – things like thermal performance and airtightness, which all contribute to the net zero carbon performance.”

The results, he says, have been unequivocal.

“The first home we assembled on site took us about 15 days, the last one took us four days.”

Richard Weeks, programme & operations director, EDAROTH

“We’ve had no non-conformances at the factory gate,” he says. “Every panel and every module that has left our factory has been on spec and in tolerance, which is something you just would not see in a traditional construction environment.”

As homes are completed, performance data is beginning to validate the approach. “We’ve done some early airtightness testing, which has proven we’re actually ahead of where we anticipated we would be,” Weeks says. “That’s supporting, with real-time data, the net zero performance of the homes.”

Speed, learning curves and community impact

Speed is the other headline benefit emerging from the live schemes – and one with implications not just for delivery programmes, but also for local communities and development finance.

At the Raven scheme, EDAROTH tracked the assembly time for each house. “The first home we assembled on site took us about 15 days,” Weeks says. “The last one took us four days.”

That learning curve has been steep – and intentional. “We’ve not only learned a lot in the process of delivering that scheme, but we’ve made some demonstrable and quite significant steps forward,” he says.

The ambition now is to go further. “In Bristol, we’re hoping to get to watertight even faster,” Weeks says.

While overall site programmes are still influenced by groundworks, utilities and external works, the speed of the superstructure is already well ahead of traditional benchmarks. “Overall, we aim to be 50% faster than traditional construction,” he says. “On the house component, we expect to beat that by a substantial amount.”

That pace brings wider benefits. “We want to get homes finished and people moving into those homes,” Weeks says. “But it’s also helpful for residents in the existing community. Being able to finish homes quickly minimises disruption, and that’s really important.”

Designed for ownership, not sale

Long-term performance and maintenance costs are critical concerns for housing associations, particularly as repair and maintenance spend continues to rise across the sector. Weeks argues that much of the problem lies in the type of housing product being delivered.

“For several decades now, social and affordable housing has relied on a model of delivery which has been optimised for market sales,” he says. “Housing associations are recognising that those homes are often not fit for their purpose. That’s why we’re seeing them stop buying section 106 homes.”

“The team demonstrated robust, fully embedded processes and procedures throughout, reflecting the strength, maturity and consistency of their operational approach.”

BOPAS

EDAROTH set out to design a different product altogether. “There’s a big difference between the product needed for social and affordable housing and the product the private sector delivers for market sales,” Weeks says. “We’ve created a product that is optimised for ownership, operation and lifecycle efficiency.”

That focus is reflected in component selection, material choices and manufacturing quality – but also in independent assurance.

A 100-year signal to clients and investors

In December, EDAROTH was awarded 100-year accreditation by BOPAS, following extensive audits of its factory processes, site delivery, design management and completed product.

“That makes us the only organisation in the UK that has a 100-year accreditation from BOPAS,” Weeks says. “That says a lot about the quality, robustness and longevity of the product we’ve developed.”

The accreditation is designed to give confidence to housing providers – but it also has implications beyond the sector. “The fact that our homes are designed to last 100 years is critical not just to providers, but to institutional investors,” Weeks says.

Following recent policy changes, he notes, government-backed social housing is increasingly being viewed as an investable asset. “Those investors are looking for reliable returns over long periods,” he says. “Crucially, because our product is accredited for 100 years, its lifespan goes beyond those investment horizons.”

BOPAS itself described EDAROTH’s performance as “outstanding”, adding: “The team demonstrated robust, fully embedded processes and procedures throughout, reflecting the strength, maturity and consistency of their operational approach.”

Scaling up – and engaging early

With the pathfinder schemes nearing completion, EDAROTH is now focused on scale. “Our model is deliberately scalable,” Weeks says. “We’re backed by AtkinsRéalis and our ambition is to be delivering thousands of homes in the coming years.”

Future schemes are likely to be larger, with a growing emphasis on aggregating smaller sites into programme-scale delivery. “By taking a programmatic view of smaller sites, we can achieve the scale we need and deliver homes at the volumes required,” he says.

Asked what advice he would give to housing associations or local authorities beginning their MMC journey, Weeks is unequivocal. “Engage early,” he says. “Engage with the benefits, but also with the differences.”

Early engagement, he argues, is essential to unlocking the full value of MMC – from funding and procurement through to site layout and delivery planning. “If you want the benefits we’ve talked about, you need to plan for them early,” he says.

For EDAROTH, the live sites in Banstead and Bristol represent more than just completed homes. They are proof that MMC can move from promise to performance – and that with the right model, SME developers can play a meaningful role in delivering safe, high quality, durable and genuinely affordable homes at pace.